Testing and Evaluation of the Crossover Technique on a 3D printed Model in Angiography

Aim and Research Question(s)

The purpose of this thesis was to find out what the requirements are for creating a 3D printed model and how testing the Crossover technique on a 3D printed model is evaluated in the angiology field. The specific research questions are: 1) How do users perceive the user-friendliness of a 3D printed model of the pelvic and leg arteries for training the Crossover technique in angiography? 2) What are the requirements for successfully completing the workflow of creating a printed 3D model based on CT data, including the planning process, segmentation, optimization, material selection, 3D printing, and post-processing of the final model?

Background

The invention of 3D printing opened new possibilities for prototyping. 3D printed models are also being used for training in the medical field [1], [2] creating new opportunities such as testing different techniques. One advantage of 3D printed models is that they can be printed individually and for specific uses, creating great independence from industry.

Methods

To perform testing of the Crossover technique in angiography, a 3D printed model was created using Stereolithography (SLA) technology. Physicians who are new to angiography, but also those who have long experience in this field, as well as radiologic technologists, tested the Crossover technique by providing special material. Subsequently, the testing was evaluated with a comprehensive questionnaire consisting of the System Usability Scale (SUS) and User Experience Questionnaire (UEQ). 23 probands tested on the 3D printed model and 21 people participated in the evaluation through the questionnaire.

Results and Discussion

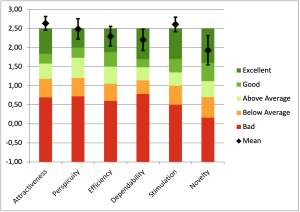

The 21 probands, 57% physicians and 47% radiologic technologists, who have been working in angiology for different periods of time, rated the testing on the 3D printed model with a SUS score of 88.33, resulting in a grade of B according to Bangor et al. [3]. According to Lewis et al. [4], the system is even classified with the grade of A+. The UEQ rating for the 3D printed model was excellent compared to the benchmark. The values for the six attributes are these: Attractiveness: 2.63, Perspicuity: 2.48, Efficiency: 2.29, Dependability: 2.20, Stimulation: 2.60 and Novelty: 1.92.

Figure 1: UEQ Score and Comparison to Benchmark

Figure 1: UEQ Score and Comparison to Benchmark

Conclusion

3D printed models are well suited for testing the Crossover technique in angiography. In a safe environment, specific techniques can be tested realistically without risking hazards to patients due to low expertise or lack of experience or exposing patients and medical staff to extended radiation exposure through X-rays. However, it should be noted that 3D printed models have certain limitations. The creation of these requires knowledge about the creation possibilities of a 3D model and the necessary 3D printing technologies to create an adequate 3D model. It was also found that testing on 3D printed models behaves differently in terms of haptics than in the patient.

References

[1] Lim et al. (2016), [2] Smith et al. (2018), [3] Bangor et al. (2009), [4] Lewis (2018)